Innovative Materials & Cutting-Edge Technologies

At PlastiForge3D, we use the latest 3D printing technology to turn your ideas into reality. Whether it’s FDM or UV Resin 3D printing materials, we provide precise, versatile, and high-quality results—from quick prototypes to full-scale production. Our modern equipment and innovative materials help us ensure every print meets top standards, offering dependable solutions for a range of industries from automotive to healthcare. Discover our 3D printing services and see how we can bring your vision to life.

FDM 3D Printing Materials

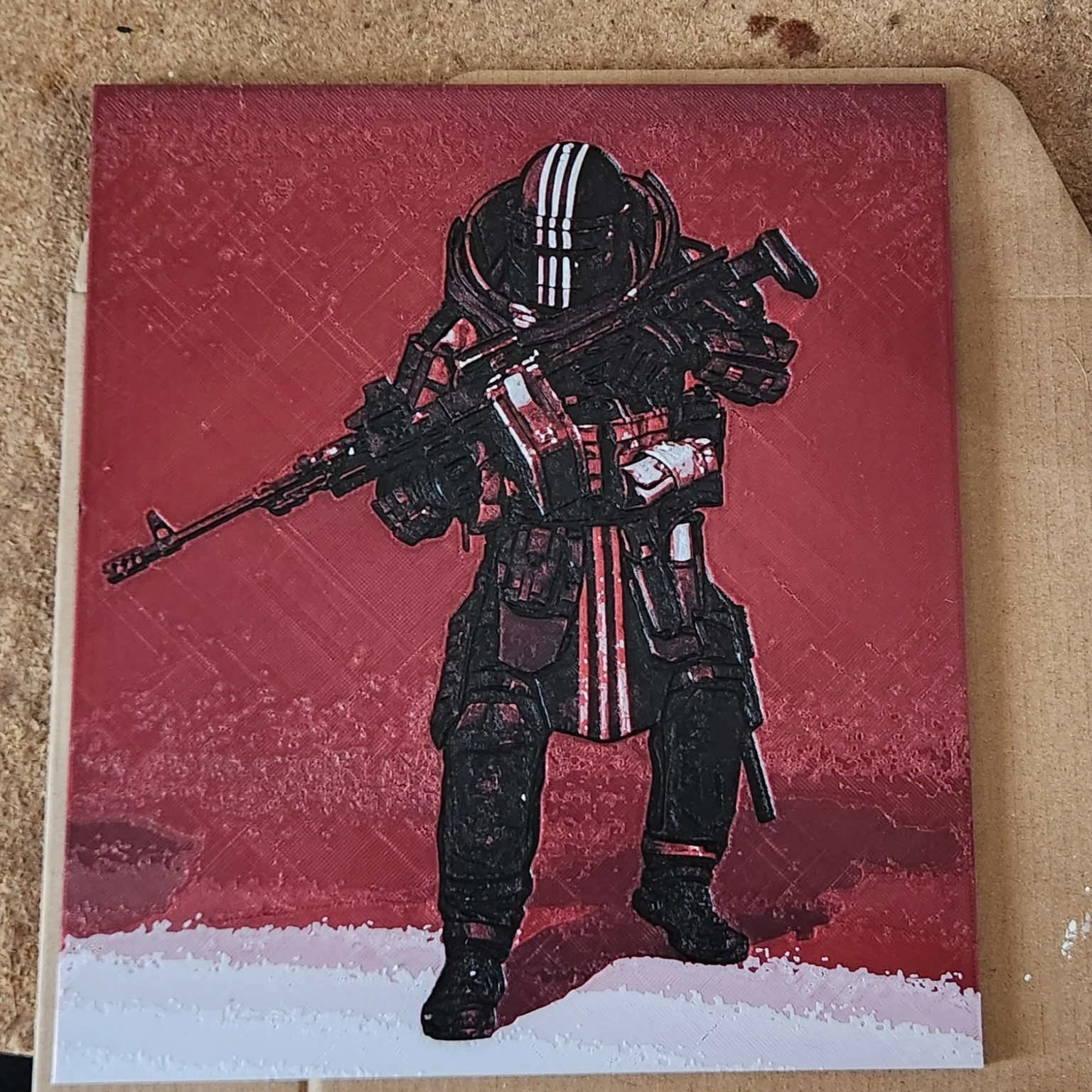

Our FDM 3D printing service combines precision with speed to produce durable parts ideal for everything from functional prototypes to final-use products. Using high-quality thermoplastics like PLA, ABS, and PETG, the FDM process creates robust, reliable prints that stand up to real-world use.

How the FDM Process Works:

Design & Preparation:

Digital models are refined for optimal printing, ensuring every detail is captured accurately.Layer-by-Layer Fabrication:

Industrial FDM printers deposit melted thermoplastic filament layer by layer, building the object with consistent strength and durability.Post-Processing:

After printing, parts can be enhanced through cleaning, sanding, or additional finishing to meet specific requirements.

Why Choose FDM?

- Durability: Perfect for functional parts requiring strength and longevity.

- Cost-Effective: Efficient material usage keeps production affordable.

- Versatility: Compatible with a range of plastics to meet various design and engineering needs.

By choosing FDM printing, you’re opting for a method that blends quality with practicality, ensuring that every print delivers both strength and reliability.

UV Resin 3D Printing Materials

Our UV Resin 3D printing service delivers high-resolution, smooth-finished prints that capture even the most intricate details. Ideal for prototypes, artistic models, and designs that demand fine features, this process uses UV-curable resins to produce exceptional quality results.

How the UV Resin Process Works:

Design & Preparation:

Digital models are optimized specifically for resin printing to ensure that every delicate detail is preserved.Layer-by-Layer Curing:

The printer deposits thin layers of UV-curable resin, which are then hardened using precise UV light exposure. This method creates incredibly detailed prints with a smooth finish.Post-Processing:

After printing, parts undergo cleaning to remove excess resin, followed by additional curing for enhanced strength and durability. Supports are carefully removed to reveal the final, polished product.

Why Choose UV Resin Printing?

- High Resolution: Perfect for projects that require intricate details and fine features.

- Smooth Finish: Achieves a flawless surface ideal for display models and prototypes.

- Versatile Resin Options: A variety of resin types—standard, tough, and flexible—allow for tailored results based on project needs.

- Precision: Delivers consistent, high-quality outputs suitable for intricate designs and professional prototypes.

By opting for UV Resin printing, you can achieve superior detail and a refined finish, making it the go-to choice for projects where precision is key.

Comparing Plastics & Resin in 3D Printing

Understanding the strengths of each 3D printing technology can help you choose the best solution for your project. Below is a clear comparison between FDM (Plastics) and UV Resin printing, along with examples of where each method shines.

Technology Comparison Table

| Feature | FDM (Plastics) | UV Resin |

|---|---|---|

| Material Types | PLA, ABS, PETG, etc. | Standard, Tough, Flexible resins |

| Durability | High Strength; ideal for functional parts | Moderate; best for detailed prototypes |

| Surface Finish | Slightly textured | Smooth and highly detailed |

| Production Speed | Fast and cost-effective | Slower due to curing process |

| Ideal Applications | Mechanical parts, prototypes | Detailed models, intricate designs |

Applications Overview

FDM 3D Printing:

Best suited for projects requiring robust, durable parts. Its cost-effectiveness and quick turnaround make it ideal for functional prototypes, mechanical components, and end-use products in industries such as automotive, aerospace, and consumer goods.UV Resin 3D Printing:

Designed for projects that demand high resolution and a pristine surface finish. This technology is perfect for detailed prototypes, jewelry, art pieces, and models where aesthetics and precision are key.

By comparing these two methods, you can decide which technology aligns with your project’s requirements. Use FDM for strength and practicality, and UV Resin for intricate details and smooth finishes. This clear comparison helps ensure you select the right process to bring your ideas to life with the best possible quality.

Ready to Bring Your Ideas to Life?

Contact us today for a personalized quote and expert advice on turning your vision into reality.